Axiometrix Solutions provides cutting-edge test and measurement solutions through its globally respected brands, Audio Precision, GRAS Sound & Vibration, and imc Test & Measurement. Unified under the Axiometrix Solutions banner, they offer one-stop solutions for all automotive testing needs, helping manufacturers and engineers avoid the costs and complications arising from fragmented systems and vendor management.

Florian Sailer, imc Strategic Product Manager Sensors & Santiago Rayes, GRAS Product Manager

As a full-service test and measurement provider, Axiometrix Solutions offers automotive measurement solutions that combine deep application expertise with a world-class portfolio of data acquisition hardware, sensors, and software to customers worldwide.

“Our customers will always find a highly experienced and reliable partner in Axiometrix Solutions - one that knows the test and measurement challenges of the automotive industry inside-out,” says Mike Flahertey, CEO of Axiometrix Solutions.

By leveraging deep industry expertise and integrated testing systems, Axiometrix Solutions enables faster test planning and streamlined setup, allowing customers to quickly deploy efficient, short-term testing campaigns without the delays and complexities of managing multiple vendors.

Fast Planning and Deployment for Speedier Innovation

The Czinger 21D hypercar test, where imc Test & Measurement provided the data acquisition solution for a two-week measurement campaign, is a good example of this. Key factors for success were imc’s fast project planning, on-site training, hardware delivery, and user commissioning. In addition, the imc automotive sensors used – the WFT-Cx Wheel Force Transducer and the imc CLSx Steering Sensor - impressed with advanced technology and an integrated approach to data acquisition and analysis. For this project, the imc data acquisition system doubled as a data sink for multiple, synchronized sensors, and as a source for the data analysis software, imc FAMOS. [Fig. 1]

Fig. 1: imc Sensors and imc CRONOSflex DAQ system as a data sink in the Czinger 21D hypercar

By analyzing the forces and moments acting on the wheels, engineers at Divergent 3D gained valuable insights into optimizing the car’s development, and studied the use of new composite materials and safety systems. Throughout the measurement campaign, the WFT sensor was used both in mobile tests and on the test bench, demonstrating its versatility and effectiveness. [Fig. 2]

Fig. 2: Testing the Czinger 21D driving dynamics with the imc wheel force transducers on the Willow Springs raceway near Los Angeles.

Meeting the High Demand for Low Noise Floors

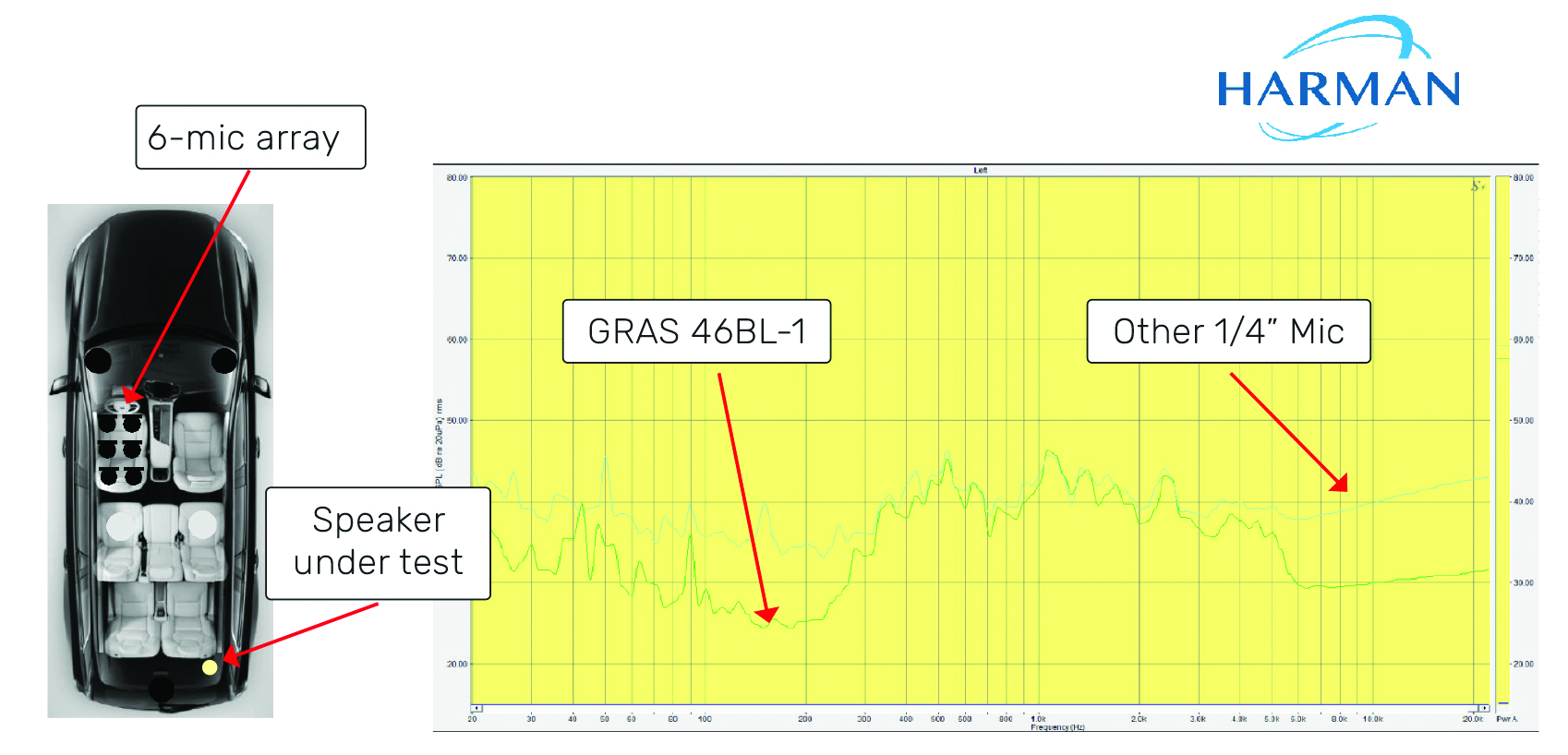

Axiometrix Solutions also contributes to the constant refinement of modern automobiles through its range of GRAS microphones, which are continuously evolving to match the needs and demands of automotive testing. Whether it's meeting regulatory demands for external vehicle noise or catering to consumer expectations for the in-cabin soundscape, Axiometrix Solutions offers turnkey setups that meet the highest standards, starting with standardized, high-quality measurement microphones from GRAS for reliable, repeatable, and comparable results. For instance, GRAS’s 46BL-1 high-sensitivity ¼" microphone, with a noise floor of just 24 dBA, stands out in the field of in-cabin testing. HARMAN International's Automotive Acoustic System Engineering department chose this microphone to calibrate their high-end in-car sound systems due to its exceptional performance. Paired with Audio Precision’s multichannel analyzers and APx500 software, the 46BL-1 provides a complete solution for in-car audio system characterization, following AES recommendations. [Fig. 4 and Fig. 5]

Fig. 4: GRAS microphone H-array placed in car for in-car acoustic measurements following AES recommendations. Microphone array and holder layout with setup dimension as shown in the AES recommendation are courtesy of JJR Acoustics.

Fig. 5: Results from in-car Acoustic test of automotive audio system made by Harman International using a 6-microphone array placed in the driver’s seat position. In such a scenario, the signal-to-noise ratio is good for a GRAS high-sensitivity 1/4" microphone like the 46BL-1. © Courtesy of Harman International.

Reliable Results in Every Condition

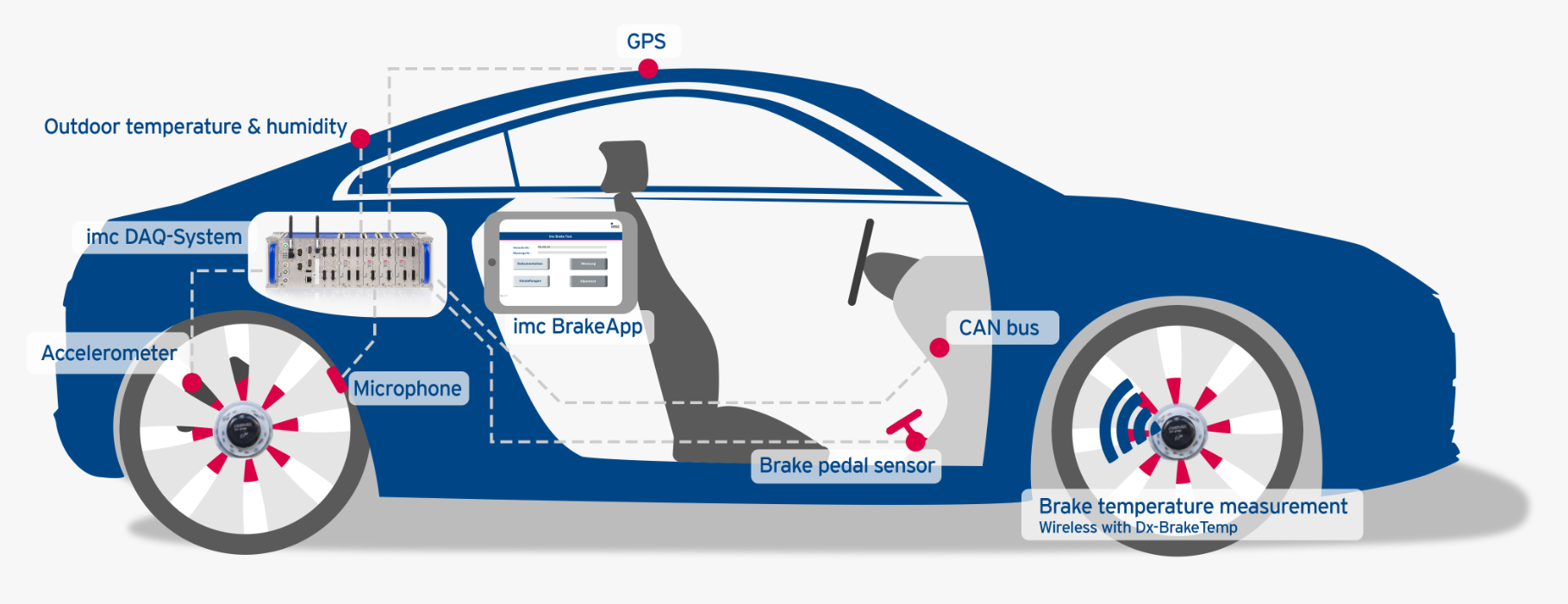

The GRAS microphone range for automotive applications is not limited to in-cabin measurements, as Santiago Rayes, Product Manager at GRAS explains: “Automotive manufacturers and their suppliers can choose from our wide range of industry firsts and unique microphones, developed especially for real life automotive test conditions. Take our line of ruggedized NVH measurement microphones: They are IP67 rated, meaning they are protected against dust and water, they are shock, drop, and vibration resistant, and they are built to perform in a temperature range going from -40 to 125 ˚ C (-40 to 257 ̊ F).” Another standout product is the GRAS 147EB microphone, built specifically for automotive brake noise testing. Its durability and precision make it the perfect companion for imc's Brake Testing System, further illustrating Axiometrix Solutions' commitment to providing reliable, integrated testing solutions. [Fig. 6]

Fig. 6: Synchronized data acquisition for brake tests using imc’s Brake Testing System and GRAS microphone.

Partnering With Customers for Long-Term Success

Completing the Axiometrix Solutions offering is Audio Precision’s (AP) full portfolio of analyzers and software for electronic digital or analog audio measurements and electroacoustic testing. Besides the above-mentioned solutions for in-car cabin testing, AP products are typically used

in the automotive industry for testing car audio system components such as amplifiers, loudspeakers, or head units. AP also offers solutions for testing automotive audio via A2B, Bluetooth, ASIO, I2S, PDM or TDM.

The examples mentioned reflect just a fraction of the comprehensive technical solutions Axiometrix Solutions offers. Therefore, to best serve the demands and challenges of their customers, they undertake comprehensive pre-sales consultations to find the right solution. Mike Flaherty, CEO of Axiometrix Solutions, emphasizes their customer-centric approach: "We listen to our customers to co-create the right solutions and offer technical support for every step of the process." This commitment to collaboration is further demonstrated by their after-sales services, including repair, calibration, product support, and user training, ensuring customers enjoy the full value of their investment.