-

KEMAR >

-

-

-

-

-

-

-

R&D

-

PE

-

PL, QA and QC

-

-

-

-

Got a question?

If you have a question, feel free to contact us:

GRAS Sound & Vibration

Headquarter | gras@grasacoustics.com

UK | sales-uk@grasacoustics.com

USA | sales-usa@grasacoustics.com

China | cnsales@grasacoustics.com

South Korea | sales-kr@grasacoustics.com

India | sales-in@grasacoustics.com

GRAS worldwide

In flight Aeroacoustics

The identification of acoustic and aeroacoustic sound sources on aircrafts has always been a challenge in in-situ environments, due to the complexity of the sources and the tough environment. Aircraft acoustic solutions are therefore critical to addressing these challenges.

Predominant sources of noise are the sounds from the engines and sounds of the wind rushing around the aircraft as it moves through the air.

Simulation is cumbersome as the acoustic models are complex and the calculation is time-consuming. Verification of the CFD (computational fluid dynamics) models by experimental measurements is required.

Acoustic sensors on the fuselage of the aircraft are used for quantifying interior and exterior noise as well as for investigating acoustic fatigue analysis. In order not to introduce unwanted turbulence noise, which affects data reliability, the sensor should be as low-profiled as possible.

During the design phase of modern aircrafts, interior noise is simulated in CFD models to establish and measure noises sources and possible solutions to reduce flow-induced noise. Areas of high airflow, that are likely to increase cabin noise, are identified allowing engineers to experiment and reshape their designs.

Acoustic fatigue analysis investigates weaknesses under acoustic stress for components and materials used on the aircraft. The results help designers and engineers to choose suitable materials and help determine the lifecycle of individual components to ensure aircraft safety.

Solutions

Due to the stochastic behavior of turbulence and flow-induced noise – also referred to as boundary layer noise – it is very difficult to quantify and understand these phenomena. In the development and testing stages of the aerospace, automotive and renewables industries. It has, therefore, been a key focus area for years – but has been hampered by a number of facts.

First of all, experimental tests have proven imprecise due to traditional microphone profile heights. Secondly, the mounting, demounting and remounting of sensors has been a tedious and not very user-friendly process. Finally, simulations and tests in anechoic wind tunnels are costly and most often require careful planning and coordination, making it very time-consuming.

GRAS measurement microphones for boundary layer applications cover UTP microphones, surface microphones and flush-mount microphones – available for surface mounting, “blind window” mounting, destructive mounting or wire-mesh applications.

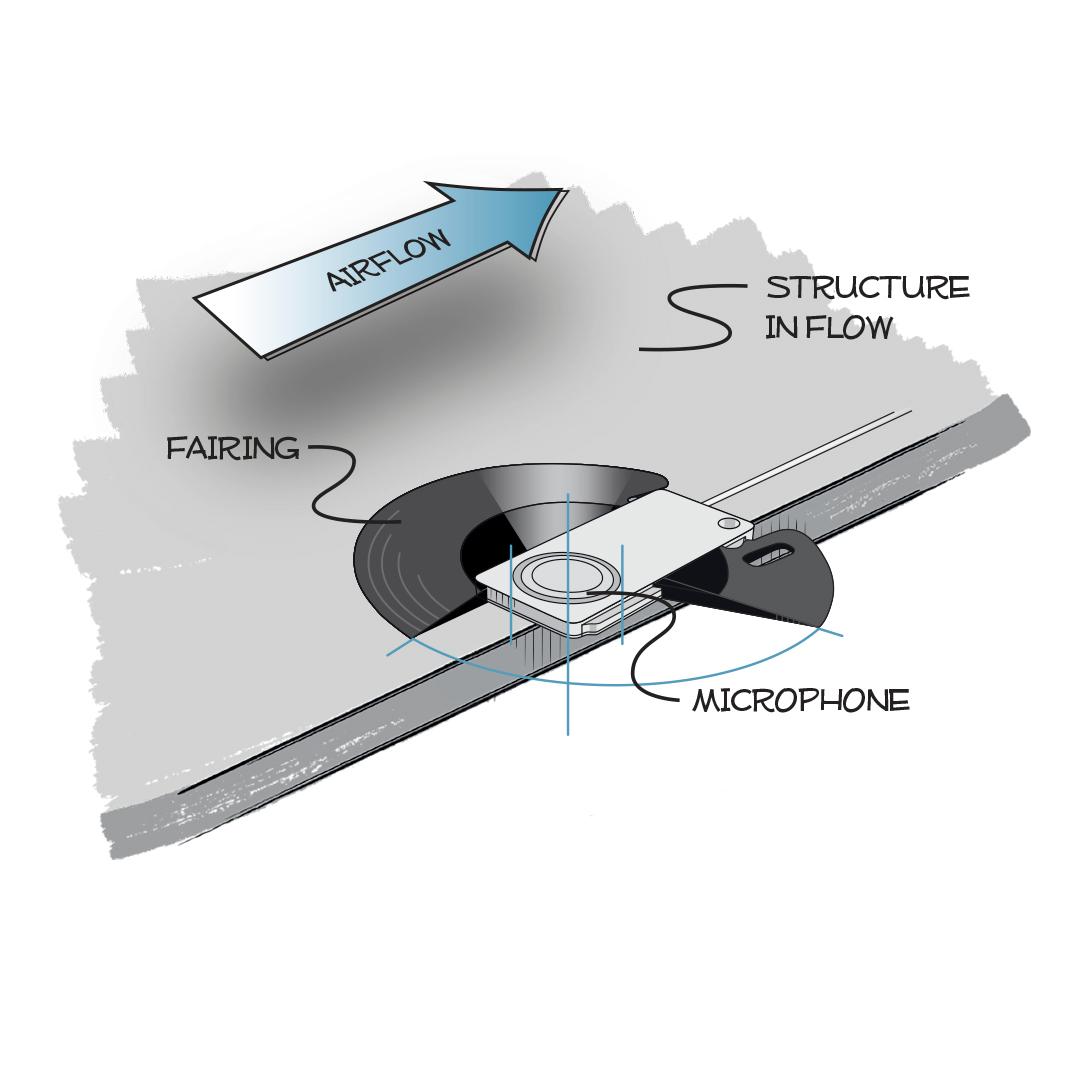

Schematic of UTP microphone, 48LA/LX-1.

UTP Microphones – Ultra-Thin Precision Microphones

The GRAS UTP microphones combine the high precision and reliability of GRAS measurement microphones with the need for extremely low-profiled (less than 1 mm) microphones with minimum turbulence influence. With their unique form factor and easy mounting, UTP microphones are specifically designed for in-situ boundary layer testing, when neutral impact and high precision is important. They combine the accuracy of condenser microphones with an extremely small form factor. All LX versions have TEDS.

> High-precision measurement microphones

> Ideal for low-boundary layer testing and confined spaces

> Fast and repeatable mounting with consistent geometry

> Easy in-situ verification

> Wide linear frequency range

> Wide dynamic range

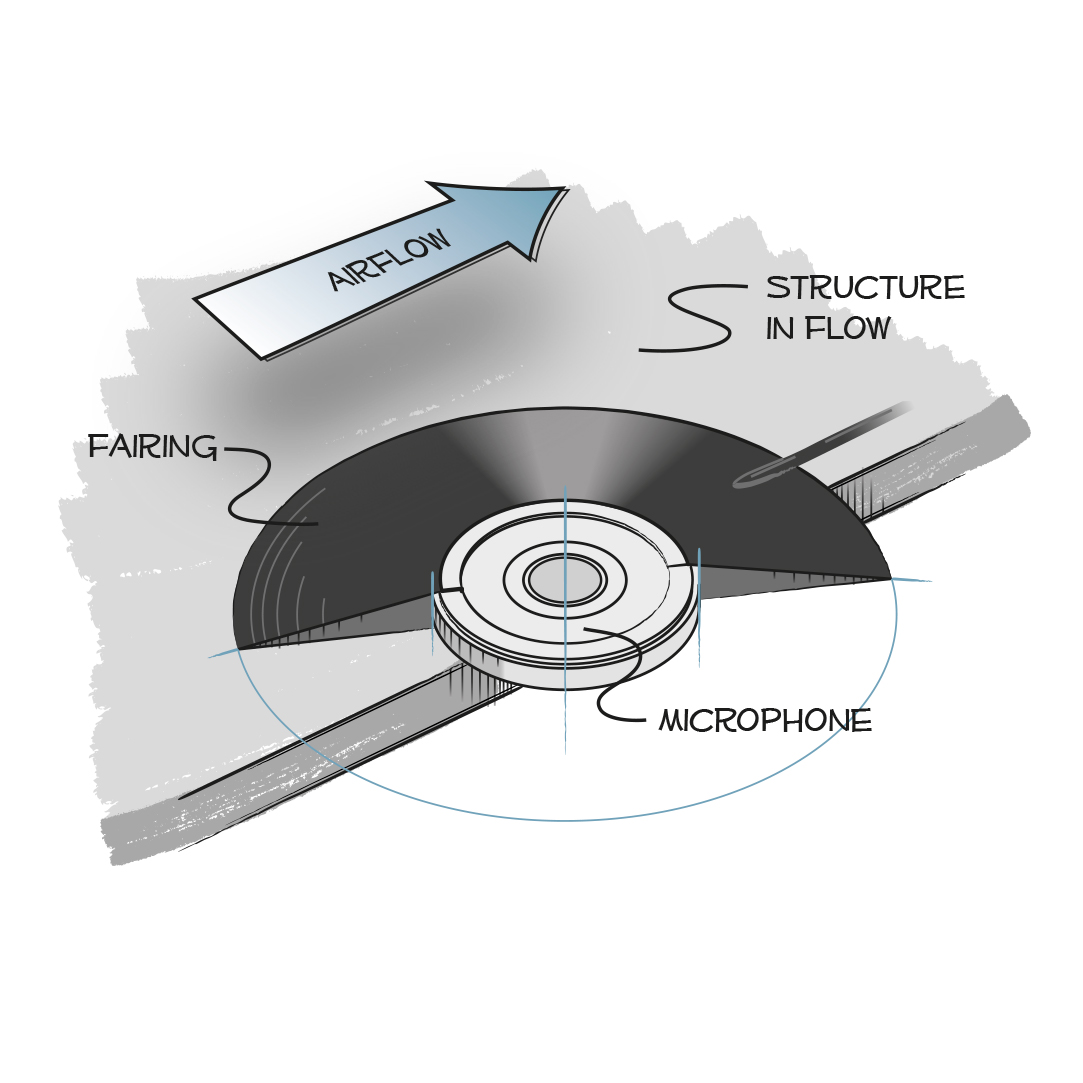

Schematic of surface microphone, 40LS.

Surface Microphones

The GRAS high-precision surface microphones are designed for in-situ boundary layer testing, where non-invasive mounting is necessary.

They are therefore also well suited for in-flow testing of full-scale objects in wind tunnels.

The height has been kept at 2.5 mm, and a fairing reduces self-generated turbulence.

> High-precision measurement microphones

> Non-invasive mounting and insignificant protrusion

> Integrated preamplifier with plug and measure functionality (TEDS)

> Wide linear frequency range

> Wide dynamic range

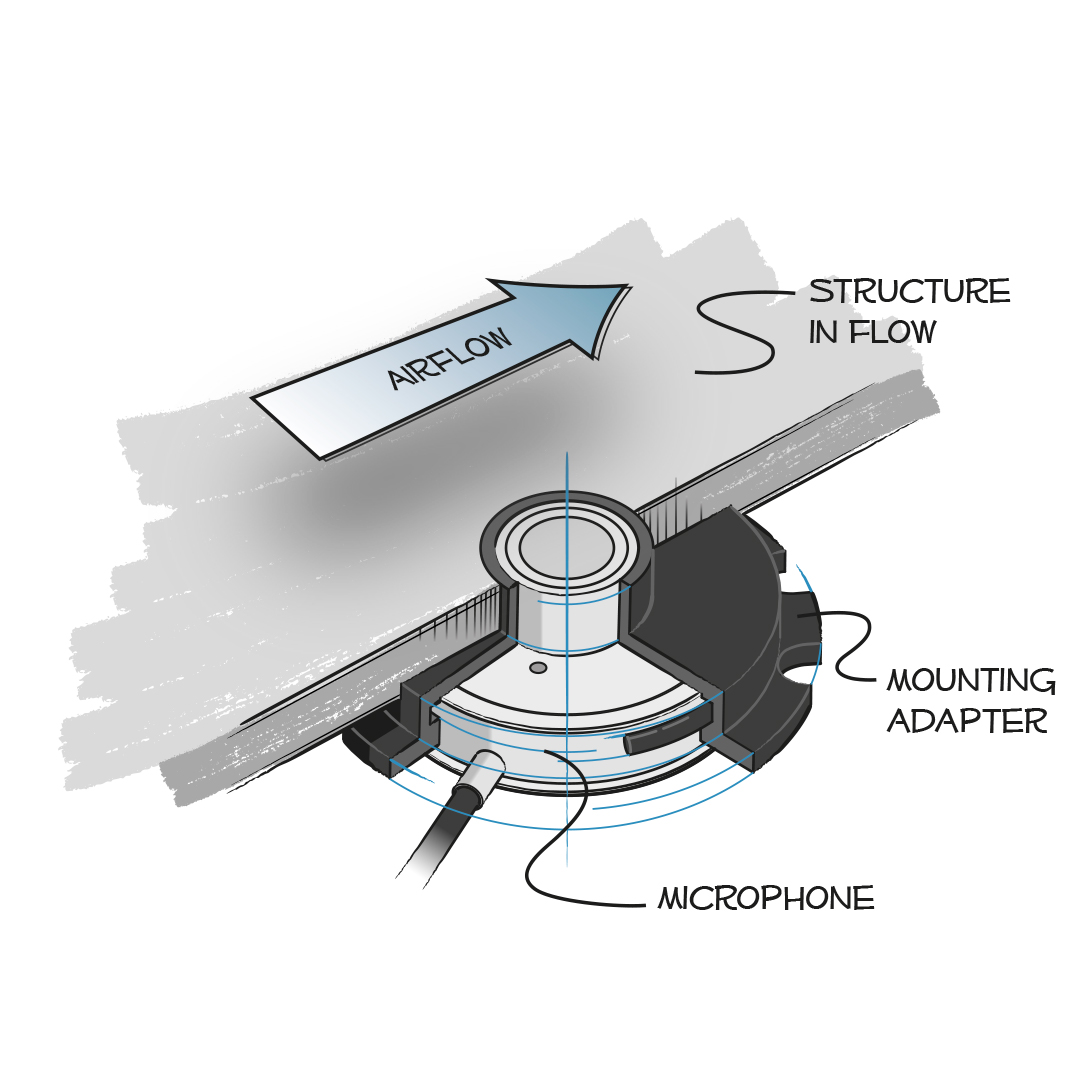

Schematic of flush-mount microphone, 47BX.

Flush-mount Microphones

This line of acoustic sensors combines the high precision and reliability of GRAS measurement microphones with the need for fitting sensors into very confined spaces and narrow structures.

With an installation height of less than 10 mm, GRAS flush-mount microphones can be integrated into virtually any design without sacrificing aerodynamic properties.

> High-precision measurement microphones

> Very low installation height

> Integrated preamplifier with plug and measure functionality (TEDS)

> Wide linear frequency range

> Wide dynamic range