Why so small?

The Accuracy at high frequencies is vital, and... post, deals with the benefits of using a ¼″ microphone compared to the more commonly used ½″ mics and measurement scenarios where those benefits outweighed the drawbacks, or where the drawbacks weren’t relevant. The obvious question, of course, is why stop at the ¼″ microphone? If there are benefits to smaller microphones, and the areas of interest in noise mitigation and sound quality trending to hi-res and higher frequencies, how small can microphones get and still be viable?

The answer, of course, involves several variables. Generally speaking, as the diameter of the microphone gets smaller, the upper frequency limits get higher. Going from a ¼″ to an ⅛″ diameter bumps the upper limits of non-specialized microphones from around 100 to 140 kHz and sound pressure levels from 166 to 175 dB. But along with the benefits is a slight decrease in sensitivity and an increase in the noise floor. Currently, the world’s smallest condenser measurement microphone is the GRAS 46DE, an ⅛″ microphone. Smaller than that seems to present some issues. From a practical point of view, actual benefits of measuring above 140 kHz are perhaps niche concerns. But another issue is the restrictions placed on the designs by the components needed for a functional microphone. Currently ⅛″ measurement microphone diaphragms are the smallest produced, but the components inside preamplifiers require more space than an eighth of an inch.

⅛″ microphones

Only GRAS and one other microphone producer currently produce ⅛″ measurement microphone sets. These microphone sets come in two design formats, either with a larger diameter preamplifier at the base of the ⅛″ microphone capsule (reminiscent of the old Apollo rockets from the lunar missions) or with a removed preamplifier connected to the microphone capsule by a cable.

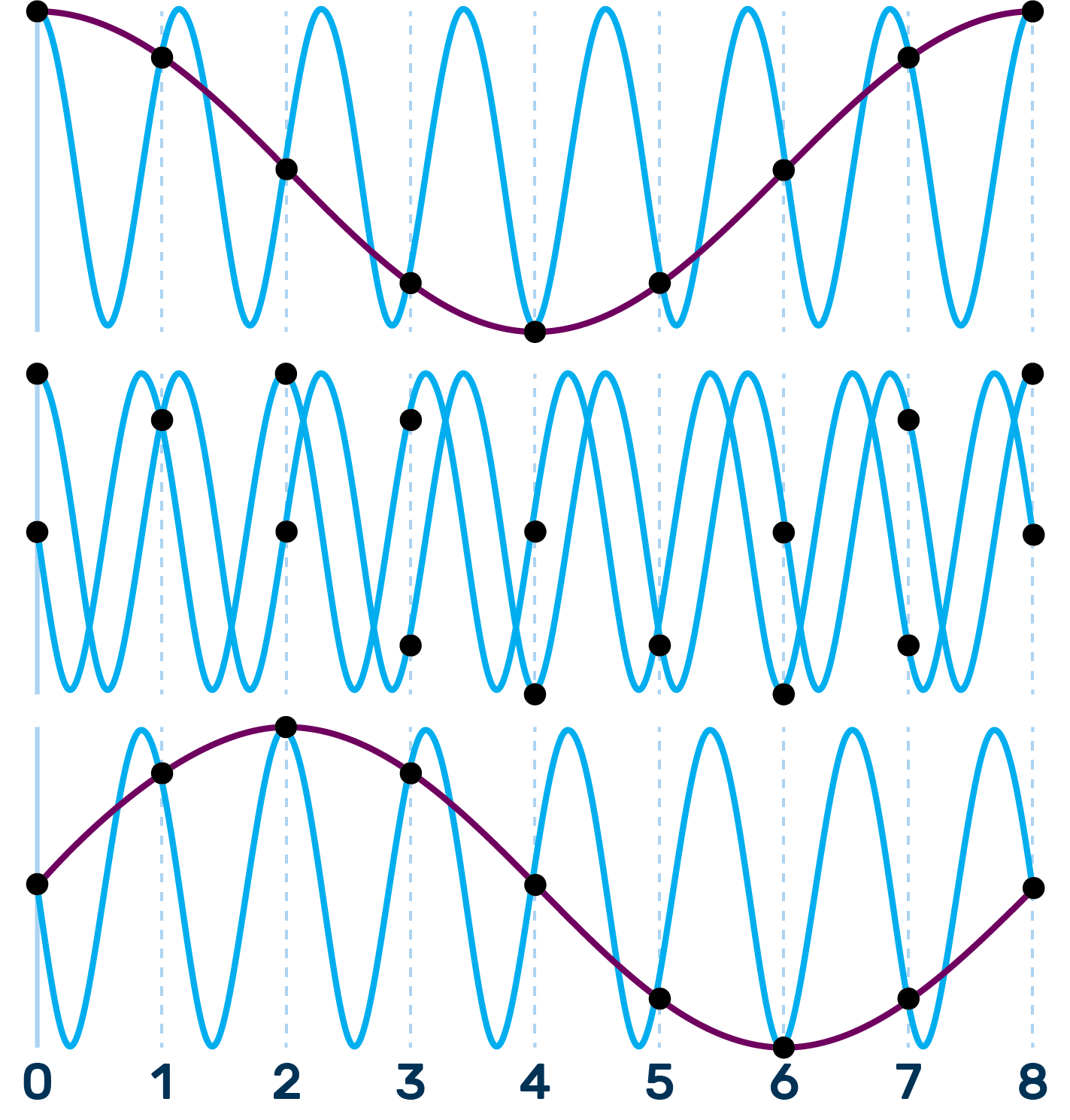

Both sets have similar performance characteristics as far as dynamic range, noise floor and upper frequency limits, but the separated microphone-preamplifier design provides the opportunity for a significant advantage. If the overall dimension remains ⅛″ for the entirety of the set (such as GRAS 46DE), the microphones take up significantly less space in the measurement environment and can be placed in smaller structures like small-scale models or narrow structures like wing or turbine blade edges. They can also be placed closer together, enabling better resolution when looking at aspects of sound in complex environments, such as when dealing with phase difference and aliasing.

To make a long story thin

In the same vein that ¼″ microphones are not a magic bullet for all applications, ⅛″ microphones have their limitations. However, they excel in applications such as impulsive noise measurements (like gunshots), aircraft turbulence, flow measurements and small-scale model measurements. Their physical properties also open up possibilities in sound data acquisition in complex environments, such as when dealing with phase difference and aliasing or exploring new ways to measure trailing edge noise emitted by wind turbines and aircraft on approach—uniquely suited thanks to their diminutive size and large range of possibility.