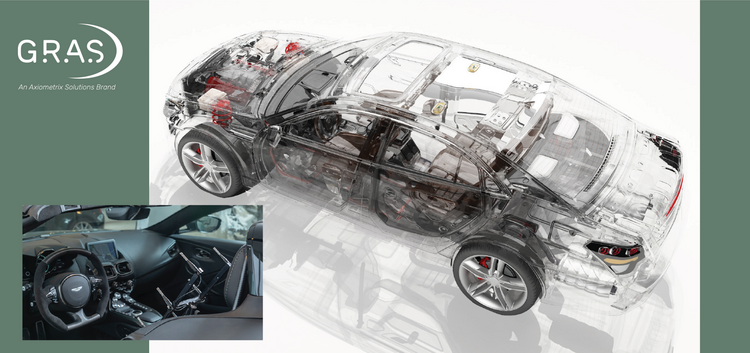

The Future of the In-Cabin Soundscape: How to Meet Evolving Consumer Expectations

The landscape of in-cabin audio is undergoing a remarkable transformation. As the automotive industry shifts from internal combustion engines to electric vehicles (EVs), the acoustic environment within vehicles is changing, too. This transition is driven not only by the technological advancements in automotive design but also by increasing consumer expectations for quieter cabins and more immersive sound experiences.